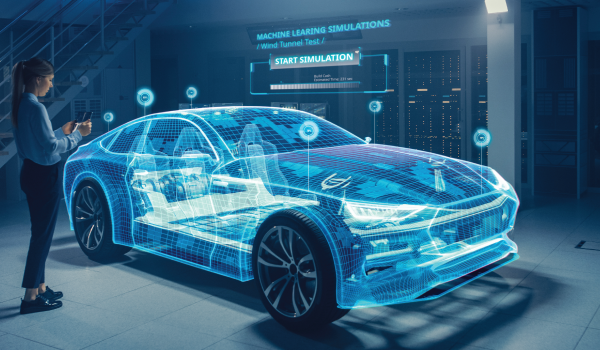

Electric Vehicle Components can be a reason causing more car manufacturers to increase operational productivity. This is due to the high need of consumers who are prone to use electric vehicles in place of traditional cars.

It is time for electronic component manufacturers and suppliers to shine more

Electric vehicles are gradually becoming a mainstream means of transportation in the world. This could be because people keep worrying about the shortages of fossil fuels that are currently going on globally.

As a result, the demand for using electric cars is growing. This triggers an increase in the productivity of car manufacturers. To make sure productivity always meets demand, manufacturers will need a large number of electronic component suppliers for vehicles.

Electronic component manufacturers and suppliers have nothing to worry about in car manufacturing since this market promises a big potential. In fact, a report from Deloitte pointed out that electric cars will reach their highest peak in 2022 and continue to rise more in 2023.

Electric Vehicle Components will need more support from electronic component suppliers due to the tendency of using more electric cars in the future.

Consumers are keen on using electric cars due to their reasonable prices. The cost of buying an electric car is quite equivalent to the combustion engine counterparts. Hence, in the context of fossil fuel issues, consumers will not be hesitant to choose an electric car over a traditional car.

The importance of batteries – one of the most crucible electronic components for electric car

Due to the increasing demand for electric vehicles, electronic component manufacturers also ponder on having plans for yielding batteries. The battery is an indispensable electric component when it comes to using an electric car. The type of battery that is used in these vehicles is Lithium-ion.

Since Lithium-ion is not much costly manufacturers are completely able to yield more to adapt to the demand of using electric vehicles without costing too much.

To sum up, it can be true to say that Electric Vehicle Components will bloom strongly to meet the demand for increasing electric vehicle car manufacturing. Besides, there is also an estimated increase in electric vehicle production, which can get to 35 million units by 2030.